Call Us Today

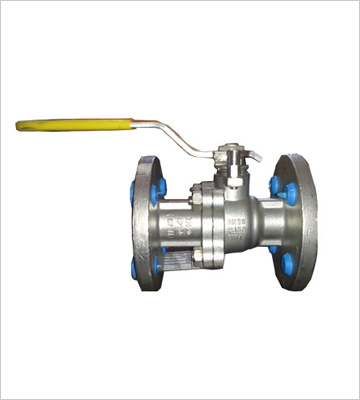

Ball Valves : Manufacturer, Supplier

Karma Automation is a leading industry engaged in the manufacturing

and supply of a range of valves essential for different process industries.

Our extensive list of products includes pneumatic valves, knife gate

valves, butterfly valves, rotary actuators and many more. Our

commitment to excellence extends seamlessly across a wide array of

sectors encompassing Engineering, Pharmaceutical, Chemicals, Food

Processing, Oil & Gas, Water Resource Management and specialized

industries.

Product Introduction :

Ball valves use a hollow ball to regulate the flow of fluids through a pipe

or duct. The ball has a hole in the middle that allows the fluid to pass

through when it is in line with the pipe. These valves are essential

components in fluid control systems known for their reliability, durability

and versatility. They offer tight shut off capabilities, making them ideal

for applications where leakage prevention is critical. They are commonly

used in various industries such as oil and gas, water treatment, chemical

processing and HVAC systems. Ball valves are preferred for their quick

operation, minimal pressure drop and ability to handle a wide range of

temperatures and pressures. With options for full port or reduced port

designs as well as different materials like stainless steel, brass or PVC,

these valves can be tailored to suit specific application requirements.

Their simple design, low maintenance needs and long service life make

ball valves a popular choice for fluid control applications where

reliability and efficiency are paramount.

Advantages :

1. Quick and easy operation : Ball valves are designed for quick and easy

operation, with a simple quarter turn of the lever or handle required to

open or close the valve.

2. High flow rates : These valves have a full bore design that allows for

high flow rates, making them ideal for applications that require high

volumes of fluid to be transported.

3. Durability : These category of valves are made from high quality

materials such as stainless steel or brass which makes them durable and

able to withstand harsh environments.

4. Low maintenance : They require minimal maintenance which helps

reduce downtime and maintenance costs.

5. Tight shut off : These tools provide a tight shut off which helps prevent

leaks and ensures the safety of the system.

6. Versatility : Ball valves are suitable for a wide range of fluids including

water, oil, gas and chemicals, making them a versatile component in

many industrial systems.

7. Resistant to high temperatures and pressures : Ball valves are resistant

to high temperatures and pressures, making them ideal for use in harsh

environments.

Applications :

1. Oil and gas industry : Ball valves are used in the oil and gas industry to

control the flow of crude oil, natural gas and other fluids.

2. Chemical industry : These devices are used in the chemical industry to

control the flow of chemicals and other corrosive fluids.

3. Water treatment industry : They are used in the water treatment

industry to control the flow of water and other fluids.

4. Pharmaceutical industry : Ball valves are used in the pharmaceutical

industry to control the flow of fluids during the manufacturing process.

5. HVAC industry : These type of mechanism are used in the HVAC

industry to control the flow of air and water in heating, ventilation and

air conditioning systems.

6. Food and beverage industry : In the food and beverage industry,these

valves to control the flow of liquids and gases during the production

process.

7. Marine industry : Ball valves are used in the marine industry to control

the flow of seawater and other fluids.