Call Us Today

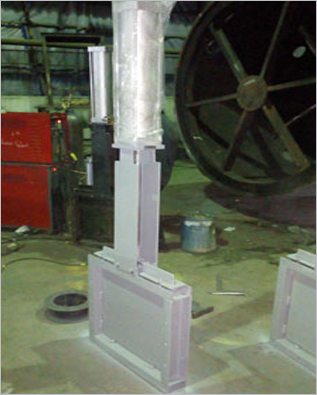

Slide Knife Gate Valves : Manufacturer, Supplier

At Karma Automation, we are a distinguished manufacturer, supplier and

exporter of high quality valves, pneumatic cylinders,ball valves, butterfly

valves, rotary actuators and many more products. Our production team

of skilled workers utilizes the latest and advanced techniques

throughout the entire production cycle, adhering to stringent quality

control procedures. The valves and components are manufactured with

the highest degree of accuracy to ensure a long life of the product and

an assured enhancement in the productivity.

Product Introduction :

Slide knife gate valves are a type of gate valve that are commonly used

in industrial applications where there is a need to control the flow of

fluids or materials. These valves are designed to provide a tight seal and

prevent leakage, making them suitable for use in applications where the

fluid or material being transported is abrasive,viscous or corrosive.

The slide knife gate valve operates by sliding a gate across the flow path

which can be done manually or with the use of an actuator. When the

gate is fully open, the fluid or material can flow freely through the valve.

When the gate is closed, it creates a tight seal that prevents any flow.

Slide knife gate valves come in a variety of sizes and materials including

stainless steel,cast iron and carbon steel, to suit different applications.

They can also be customized to meet specific operating conditions such

as high temperatures or pressures.

Advantages :

1. Tight shut-off : Slide knife gate valves provide a tight shut-off which

prevents any leakage of the fluid or material being transported. This

makes them ideal for use in applications where the fluid or material is

abrasive,viscous or corrosive.

2. Low maintenance : Blade gate valves are designed to be low

maintenance, with few moving parts and simple construction. This

reduces the need for frequent repairs or replacements which can save

time and money.

3. High-density handling : Slide blade valves are capable of handling high

density slurries and solids, making them ideal for use in the mining, pulp

and paper and wastewater treatment industries.

4. Customizable : These type of valves can be customized to suit specific

operating conditions such as high temperatures or pressures. They are

available in a variety of sizes and materials including stainless steel, cast

iron and carbon steel.

5. Cost-effective : Slide knife gate valves are generally more cost-effective

than other types of valves, making them a popular choice for many

industrial applications.

Applications :

1. Mining : Slide knife gate valves are used in the mining industry to

control the flow of slurries and tailings. They are ideal for handling

abrasive and corrosive materials, making them suitable for use in mining

applications.

2. Pulp and paper : These tools are used in the pulp and paper industry to

control the flow of wood chips, pulp and other materials. They are

designed to handle high-density slurries and solids, making them ideal

for use in this industry.

3. Wastewater treatment : Slide knife gate valves are used in wastewater

treatment plants to control the flow of sewage and other fluids.They are

designed to handle corrosive and abrasive materials, making them ideal

for use in this application.

4. Chemical processing : These devices are used in chemical processing

plants to control the flow of chemicals and other materials. They are

available in a variety of materials including stainless steel and plastic,

making them suitable for use in corrosive environments.

5. Food and beverage : Such type of blade valves are used in the food and

beverage industry to control the flow of liquids and solids. They are

designed to meet strict hygiene and safety standards, making them

suitable for use in this industry.