Call Us Today

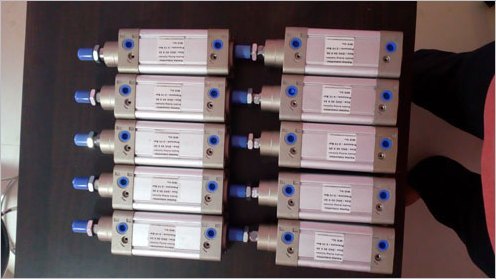

ISO DNC Pneumatic Cylinders: Manufacturers, Supplier

Karma Automation specializes in manufacturing and supplying of ball

valves, butterfly valves, rotary actuators, knife gate valves and other

products to cater to the diverse automation needs of varied process

industries. We are experts in developing and designing of a range of

automation valves. Through our stringent quality control practices, we

have secured an noteworthy position in the industry. We rigorously

adhere to industry standards and trading policies, making us a trusted

entity in the market.

Product Introduction :

ISO DNC pneumatic cylinders are a type of pneumatic cylinder that

conforms to the ISO 6431 standard. These cylinders are designed to

provide reliable and efficient linear motion in industrial applications.

They come in a range of sizes and styles, making them suitable for use in

a wide range of automation systems. ISO DNC pneumatic cylinders are

known for their high force output, fast response time and cost

effectiveness. They are also safe and reliable which makes them ideal for

use in applications where safety is a top priority. Typically made from

high quality materials such as aluminum or stainless steel, these

cylinders are durable and long lasting. They can be customized to meet

the specific needs of an application, making them an excellent choice for

many industries including manufacturing, automotive and food

processing.

The square aluminum pipe without a tie rod offers good corrosion

resistance. The cylinders also feature a mounting groove on the cylinder

tube, making it convenient to install reed sensor switches without

additional mounting brackets. ISO DNC pneumatic cylinders adhere to

international standards established by the International Organization for

Standardization. These standards ensure that manufacturers produce

cylinders, allowing for interchangeability and compatibility with various

mounting accessories and components.

Advantages :

1. High force output : ISO DNC pneumatic cylinders are known for their

high force output which makes them ideal for applications that require

high levels of force.

2. Fast response time : These cylinders have a fast response time which

makes them suitable for applications that require quick and precise

movement.

3. Cost effective : ISO DNC pneumatic cylinders are cost effective which

makes them an excellent choice for applications that require high levels

of efficiency at a lower cost.

4. Safe and reliable : These cylinders are designed to be safe and reliable,

which makes them ideal for use in applications where safety is a top

priority.

5. Durable and long lasting : Typically made from high quality materials

such as aluminum or stainless steel, ISO DNC pneumatic cylinders are

durable and long lasting.

6. Customizable : These category of cylinders can be customized to meet

the specific needs of an application, making them an excellent choice for

many industries.

7. Easy to maintain : These cylinders are easy to maintain which helps

reduce downtime and maintenance costs.

8. Energy-efficient : ISO DNC pneumatic cylinders are energy-efficient,

which helps reduce overall energy consumption and costs.

Applications :

1. Material handling : ISO DNC pneumatic cylinders are commonly used in

material handling applications such as conveyor systems, palletizers and

packaging machines.

2. Automotive industry : These cylinders are used in the automotive

industry for applications such as assembly lines, stamping presses and

welding equipment.

3. Food and beverage industry : ISO DNC pneumatic cylinders are used in

the food and beverage industry for applications such as bottling and

packaging machines.

4. Printing industry : These cylinders are used in printing presses for

applications such as paper feeding and ink transfer.

5.Textile industry : ISO DNC pneumatic cylinders are used in the textile

industry for applications such as spinning, weaving and dyeing.

6. Medical industry : These cylinders are used in the medical industry for

applications such as patient lifts, hospital beds and medical equipment.

7. Aerospace industry : ISO DNC pneumatic cylinders are used in the

aerospace industry for applications such as aircraft assembly and

maintenance.

DIMENSIONS SHEET

| Bore | A | A1 | B | C | D | E | F | G | H | I | J | K |

| 32 | 140 | 187 | 47 | 93 | 28 | 32 | 15 | 27.5 | 22 | 17 | 6 | M10 X 1.25 |

| 40 | 142 | 191 | 49 | 93 | 32 | 34 | 15 | 27.5 | 24 | 17 | 7 | M12 X 1.25 |

| 50 | 150 | 207 | 57 | 93 | 36 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16 X 1.5 |

| 63 | 153 | 210 | 57 | 96 | 36 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16 X 1.5 |

| 80 | 182 | 257 | 75 | 107 | 47 | 54 | 21 | 33 | 40 | 26 | 10 | M20 X 1.5 |

| 100 | 188 | 263 | 75 | 108 | 47 | 54 | 21 | 33 | 40 | 26 | 10 | M20 X 1.5 |

| 125 | 239 | 330 | 104 | 136 | 56 | 71 | 32 | 40 | 54 | 36 | 9 | M27 X 2 |

| 160 | 291 | 412 | 121 | 162 | 62 | 92 | 60 | 50 | 72 | 50 | 16 | M36 X 2 |

| 200 | 272 | 409 | 132 | 140 | 75 | 117 | 30 | 41 | 72 | 50 | 16 | M36 X 2 |

| Bore | L | M | N | O | P | Q | R | S | T | V | W | Z |

| 32 | M6 X 1 | 9.5 | 13.7 | G1/8 | 3.5 | 7.5 | 7 | 45 | 33 | 12 | 10 | 21 |

| 40 | M6 X 1 | 9.5 | 13.5 | G1/4 | 6 | 8.2 | 9 | 50 | 37 | 16 | 14 | 21 |

| 50 | M6 X 1 | 9.5 | 13.5 | G1/4 | 8.5 | 8.2 | 9 | 62 | 47 | 20 | 17 | 23 |

| 63 | M8 X 1.25 | 9.5 | 13.5 | G3/8 | 7 | 9.5 | 9 | 75 | 56 | 20 | 17 | 23 |

| 80 | M10 X 1.5 | 11.5 | 16.5 | G3/8 | 10 | 9.5 | 14 | 94 | 70 | 25 | 22 | 29 |

| 100 | M10 X 1.5 | 11.5 | 16.5 | G1/2 | 11 | / | 14 | 112 | 84 | 25 | 22 | 29 |

| 125 | M12 X 1.75 | 21 | 16.5 | G1/2 | / | / | / | 140 | 110 | 32 | 28 | 33 |

| 160 | M16 X 2 | 25 | 26 | G3/4 | / | / | / | 180 | 140 | 40 | 36 | 38 |

| 200 | M16 X 2 | 25 | 22.5 | G3/4 | / | / | / | 220 | 175 | 45 | 42 | 42 |

SPECIFICATION

| Motion Pattern | Double Action / Single Acting Extrusion type Single Acting Drawing - in Type |

| Working Medium | Air |

| Operating Voltage Range Double Action | 0.1~0.9MPa |

| Operating Voltage Range Single Action | 0.2~0.9MPa |

| Ensured Pressure Resistance | 1.35Mpa |

| Operating Temperature Range | -5~70oC |

| Operating Speed Range Double Action | 300~500mm/s 300~350mm/s 300~250mm/s |

| Operating Speed Range Single Action | 100~500mm/s |

| Buffer Type | Fixed Type Buffer |

| Port Size | M5 X 0.5 G1/8 G1/4 G3/8 |