Call Us Today

Karma Automation Industries stands out as a prominent player in the

valve industry, focusing on the manufacturing and supply of a diverse

array of products including ball valves, gate valves, globe valves,

pneumatic cylinders,rotary actuators, butterfly valves and more. Our

operations at Karma Automation are centered around client satisfaction.

We customize our valves to meet the specific needs of our customers

and ensure timely delivery according to agreed deadlines. Our highly

skilled technical and support staff work diligently to provide the most

innovative solutions while reinforcing our commitment to our

customers.

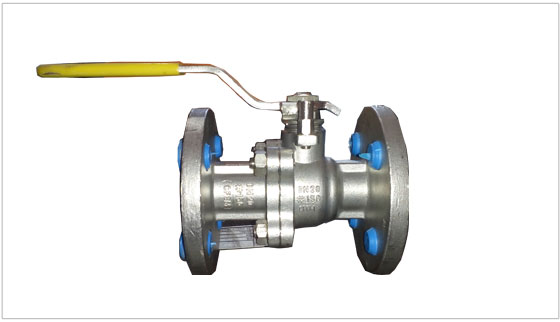

Product Introduction :

Manual ball valves are essential components in various fluid control

systems, widely used in industrial, commercial and residential

applications. These valves are designed to regulate the flow of liquids

and gases through a pipeline by using a spherical disc known as a ball,

which has a hole or port through its center. When the valve is open, the

hole aligns with the flow direction, allowing fluid to pass through and

when the valve is closed, the ball rotates to block the flow. The ball is

usually equipped with seals or O-rings that ensure a tight closure,

preventing leaks when the valve is in the closed position. Typically made

from materials such as brass, stainless steel or PVC, the manual ball

valves are durable and resistant to corrosion, making them suitable for

various environments. Manual ball valves come in various sizes,

configurations and connection types such as threaded, flanged or

welded, allowing for flexibility in installation and use.

Here are some advantages of manual ball valves :

1. Easy to operate : Manual ball valves are easy to operate, with a simple

quarter-tuqrn of the lever or handle required to open or close the valve.

2. Cost effective : They are generally less expensive than their automated

counterparts, making them a cost effective option for many industrial

applications.

3. Reliable : These valves offer precise control over fluid flow, making

them a dependable choice for various applications.

4. Low maintenance : Manual ball valves require minimal maintenance

which helps reduce downtime and maintenance costs.

5. Suitable for a wide range of fluids : These tools are suitable for a wide

range of fluids including water, oil, gas and chemicals, making them a

versatile component in many industrial systems.

6. Resistant to high temperatures and pressures : These are resistant to

high temperatures and pressures, making them ideal for use in harsh

environments.

Some common applications of manual ball valves include :

1. Plumbing Systems : Manual ball valves are used in residential,

commercial and industrial plumbing systems for tasks such as isolating

water supply lines, controlling water flow to fixtures and regulating

water distribution within buildings.

2. Irrigation Systems : These valves are employed in irrigation systems for

agricultural, landscaping and gardening purposes to control the flow of

water to different zones, ensuring efficient water distribution and

conservation.

3. HVAC Systems : Manual ball valves play a crucial role in heating,

ventilation and air conditioning systems for tasks like regulating coolant

flow, controlling air supply and isolating sections of the system for

maintenance or repair.

4. Process Control : In industrial processes, manual ball valves are used to

control the flow of liquids or gases in pipelines, tanks and equipment,

allowing operators to adjust flow rates, isolate sections and ensure

process efficiency.

5. Chemical Processing : Manual ball valves are utilized in chemical plants

and facilities to control the flow of chemicals, acids and corrosive fluids,

providing reliable shut-off and flow control in hazardous environments.

6. Water Treatment : These valves are integrated into water treatment

systems for tasks such as diverting water flow, controlling chemical

dosing and isolating filtration units, ensuring proper treatment and

distribution of water.

7. Fire Protection Systems : Manual ball valves are essential components

in fire protection systems for tasks like opening or closing water supply

lines to sprinklers, hydrants or standpipes in case of fire emergencies.

8. Oil and Gas Industry : In the oil and gas sector, these valves are

employed in pipelines, refineries and drilling operations for tasks like

flow control, isolation and emergency shut-off to ensure safe and

efficient operations.