Call Us Today

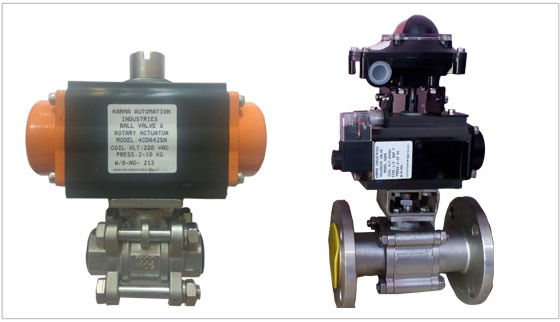

Pneumatic Ball Valves : Manufacturer, Supplier

Karma Automation Industries is one of the leading automation valve

manufacturer, supplier and exporter in India. We have been pioneers in

the production of a range of ball valves,butterfly valves, rotary actuator,

knife gate valve,pneumatic cylinders and more to meet the diverse

automation demands of the process industries. We have always been

relentless in our commitment to quality. Over the years, we have gained

valuable experience and a reputation for being a reputed valve

manufacturer among our customers.

Product Introduction :

Pneumatic ball valves are specialized valves that utilize compressed air

to operate the opening and closing mechanism of the valve, making

them ideal for automated systems in various industrial applications.

These valves feature a spherical disc with a hole through its center,

which allows for efficient flow control when aligned with the pipeline.

The pneumatic actuator, powered by compressed air, enables quick and

precise operation, providing a reliable solution for processes that require

rapid response times. Pneumatic ball valves are known for their

durability and ability to handle high-pressure environments, making

them suitable for applications in varied sectors . Additionally, they can

be easily integrated into control systems, allowing for remote operation

and monitoring which enhances overall system efficiency. With their

robust design and effective performance, pneumatic ball valves play a

crucial role in optimizing fluid control processes across various

industries.

Advantages of Pneumatic Ball Valves :

1. Quick Operation : Pneumatic ball valves feature a quarter-turn design,

allowing for rapid opening and closing which is essential for processes

that require immediate response.

2. Excellent Sealing Capabilities : These valves provide reliable sealing,

minimizing the risk of leaks and ensuring consistent performance even

under high-pressure conditions.

3. Durability : Pneumatic ball valves are highly durable and can withstand

harsh environments, making them suitable for industries such as oil and

gas, chemical processing and water treatment.

4. Ease of Integration : They can be easily integrated into automated

systems, enabling remote operation and control which enhances

operational efficiency and safety.

5. Minimal Maintenance : Due to their simple design and robust

construction, pneumatic ball valves require minimal maintenance,

contributing to lower operational costs over time.

6. Versatility : These valves can be customized to meet specific

application requirements including size, material and actuator type,

making them adaptable to a wide range of fluid control needs.

7. Cost-Effectiveness : The combination of speed, reliability and ease of

use makes pneumatic ball valves a cost-effective choice for many

industrial applications.

Applications of Pneumatic Ball Valves :

1. Oil and Gas Industry : Pneumatic ball valves are widely used in the oil

and gas sector for controlling the flow of crude oil, natural gas and other

fluids in pipelines and processing facilities.

2. Chemical Processing : In chemical plants, pneumatic ball valves are

employed to regulate the flow of various chemicals and corrosive

substances. Their durability and resistance to harsh environments

ensure safe and efficient handling of reactive materials.

3. Water Treatment : These valves are commonly used in water treatment

facilities to control the flow of water and chemicals during purification

processes.

4. Pharmaceutical Manufacturing : In pharmaceutical applications,

pneumatic ball valves are used to manage the flow of ingredients and

chemicals in production processes.

5. HVAC Systems : Pneumatic ball valves are employed in heating,

ventilation and air conditioning (HVAC) systems to control the flow of air

and fluids .Their quick response times contribute to efficient

temperature regulation and energy savings.

6. Power Generation : In power plants, pneumatic ball valves are used to

control steam and water flow in various processes, including cooling

systems and turbine operations.

7. Mining and Mineral Processing : These valves are utilized in mining

operations to control the flow of slurries and other materials which

makes them suitable for harsh mining conditions.